neoVI FIRE 3 COMPUTE

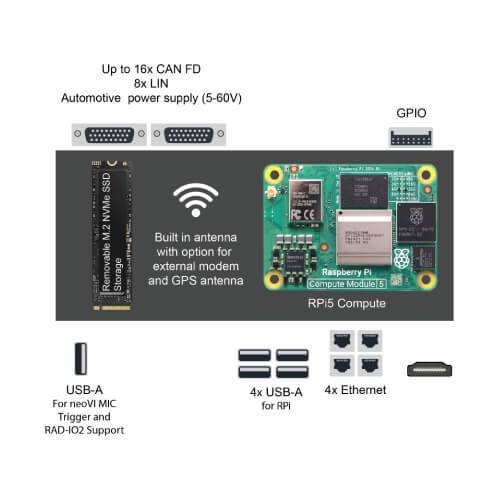

Multi-Protocol Vehicle Interface, Gateway, and Data Logger with Embedded Edge IntelligenceThe neoVI FIRE 3 COMPUTE redefines what a vehicle interface can do. We started with the world’s most powerful vehicle network interface with 16x CAN FD, 8x LIN, and ethernet ports and integrated a Raspberry Pi 5 Compute Module (CM5) directly inside.

The result is a single, rugged device that doesn’t just capture data. It processes, understands, and acts on it in real-time. Move your Python scripts, AI models, and custom logic off the laptop and into the vehicle for unparalleled power and flexibility.

Benefits

- Logs only critical events, reducing data volume and analysis time

- PC-free operation with remote control via SSH or web UI

- Simplifies vehicle network analysis and diagnostics

- Reliable standalone data logging without external systems

- Automatic wireless data transfer via Wi-Fi/Ethernet

- Enables ECU/vehicle simulation without a physical vehicle

- Captures real-world in-vehicle data continuously

- Speeds up fleet-wide testing and validation

- Improves fleet monitoring and management

- Compatible with OEM diagnostic tools via J2534 and RP1210

Features

- 16x DW CAN / CAN FD channels with TJA1463 transceivers, supporting CAN SIC (ISO 11898-2:2024)

- 16x software enabled CAN termination

- 8x LIN channels

- 2x SW CAN*

- 2x LSFT CAN*

- 2x DoIP activation line

- 2x 1 Gb 10/100/1000BASE-T, 1x 10/100BASE-Tx for use with DoIP, XCPoE and more

- 2x Full-size SD card slots. SD 3.0 compatible and supporting up to 2 terabytes of total storage. Up to 800 Mbps logging performance. (1 x 64 GB SD card included standard)

- Onboard CM5 eMMC flash memory

- User replaceable M2 NVMe 2.0 SSD up to 4TB

- 4x 1000BASE-T with Generalized Precision Timing Protocol (gPTP) support

- 4x USB 3.0 ports

- 1x USB Type-A connector for accessories such as RAD-IO2 or neoVI MIC2 manual trigger

- 10x Programmable tri-color LEDs show link, error, and activity status

- 9 DOF IMU (accelerometer, gyroscope, and magnetometer)

Automotive Edge Computing, Logging, and Simulation

The neoVI FIRE 3 COMPUTE evolves the traditional standalone mode into a fully capable Edge Computing Station. By integrating a Raspberry Pi 5 Compute Module (CM5) directly alongside the vehicle interface, it allows you to run complex Linux applications, Python scripts, and AI models directly on the device—eliminating the need for a laptop in the vehicle.

High Performance Headless Operation

While traditional adapters only capture data, the neoVI FIRE 3 COMPUTE processes it. You can run real time scripts to simulate complex gateways, execute Restbus simulations for missing ECUs, or perform automated diagnostic sequences autonomously. The device supports headless (no PC) operation, allowing you to deploy it as a standalone test station or data logger that manages itself via SSH or a web interface hosted on the internal Pi.

Advanced Storage

Data logging capacity is significantly expanded. In addition to the two full size SD card slots (supporting up to 2 terabytes), the device includes an M.2 NVMe 2.0 SSD slot and 64GB of eMMC flash memory for high speed, massive storage of video, lidar, or CAN FD data..

Dual Layer Intelligence: CoreMini and Compute

The system offers two layers of scripting power to fit your unique needs:

- CoreMini: Handling the micro second critical tasks, the hardware level scripting environment ensures real time network interaction and 25ns hardware timestamping.

- Compute Module: For complex logic, proprietary protocol decoding, or AI driven data filtering, you can utilize the full power of the Raspberry Pi 5 ecosystem.

Remote Connectivity and Fleet Management

The device features internal dual band 802.11a/b/g/n WiFi (with options for external antennas) and Gigabit Ethernet ports for local connections. To extend connectivity further, the optional RAD 4G modem accessory adds external cellular capability. This connectivity ecosystem is designed to work seamlessly with Wireless neoVI, allowing for server based fleet management, remote software updates, and automatic data upload without any driver interaction. A high precision GPS provides accurate location correlation for your test data within wirelessneoVI, while the internal buzzer and programmable LEDs provide immediate feedback to drivers during test runs.

| Part Number | Description |

| NEOVI-FIRE3-C | Multi-Protocol Vehicle Interface, Gateway, and Data Logger with Embedded Edge Intelligence |

Specifications subject to change; please contact Intrepid for the latest information. All trademarks are the property of their respective owners.